Diamond Cutting Process

Diamond cutting is the term for changing a diamond from a rough stone to a faceted gemstone – a ‘Polished Diamond’.

The process is complicated because diamonds are such a rigid material. Faceting and shaping them requires a lot of knowledge, skill, equipment, and technique to complete correctly. The diamond-cutting process consists of five steps: Planning, Cleaving, Bruting, Polishing, and Final Inspection.

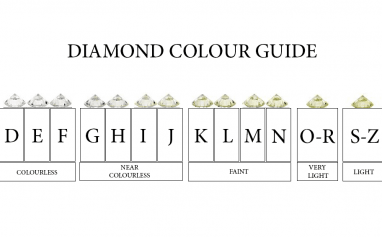

Manufacturers analyze a rough diamond while planning, focusing on two things. The first focus is the diamond’s return once it has been cut. The second is how quickly the diamond will be sold once completed. Manufacturers use 3D technology to scan diamonds onto a program, allowing them to identify each inclusion on the soon-to-be gemstone. Once the diamond cutting has begun, colour restoration is critical in maintaining value and authenticity.

Cutting diamonds is a precise and intricate craft that requires skill, knowledge, and patience. From the rough diamond crystal to the dazzling finished gemstone, a diamond’s journey through the cutting process is a fascinating blend of artistry and science. This blog post will explore the steps in cutting diamonds, from the initial planning stage to the final polishing, highlighting the techniques and considerations that shape each facet of these precious gemstones.

The process of cutting diamonds begins with selecting the rough diamond crystal. This is a crucial step, as the cutter must assess the rough stone’s shape, size, and internal characteristics to determine the most suitable cut. Factors such as clarity, colour, and potential inclusions are carefully evaluated to maximize the yield and quality of the finished diamond.

The cutting begins with the planning stage once the rough diamond has been selected. This involves mapping out the desired shape and proportions of the finished diamond, taking into account its natural characteristics and the market demand for specific shapes and styles. The goal is to achieve the optimal balance between maximizing carat weight and enhancing the diamond’s brilliance, fire, and scintillation.

After the planning stage, the rough diamond is cleaved or sawn into smaller pieces, known as preforms, to prepare them for the shaping process. This step requires precision and expertise to ensure that the diamond is divided along its natural planes, minimizing waste and preserving as much of the valuable material as possible.

Next comes the shaping stage, where the preforms are transformed into recognizable diamond shapes such as round, princess, emerald, or marquise. This is accomplished using various cutting tools and techniques, including sawing, grinding, and polishing, each designed to remove material and create the desired facets and angles.

The most critical aspect of the cutting process is the creation of the diamond’s facets, which are small, flat surfaces that reflect and refract light to produce the stone’s characteristic brilliance and sparkle. Each facet must be carefully aligned and polished to precise angles and proportions to optimize the diamond’s optical properties and maximize its beauty.

One key factor influencing a diamond’s brilliance and fire is its symmetry, which refers to the uniformity and alignment of its facets. Achieving perfect symmetry requires meticulous attention to detail and the use of specialized equipment, such as optical measuring devices and computer-aided design (CAD) software, to ensure that each facet is positioned correctly relative to the others.

Once the shaping and faceting stages are complete, the diamond undergoes a series of polishing steps to enhance its lustre and shine. This involves smoothing out rough surfaces and removing scratches or imperfections to achieve a flawless finish. The final polish brings out the diamond’s natural beauty and brilliance, transforming it into a dazzling gemstone that sparkles with life and light.

In addition to shaping and polishing, the cutting process may include treatments such as laser drilling or fracture filling to improve the diamond’s clarity or colour. These treatments are carefully regulated and disclosed to consumers to ensure transparency and ethical sourcing practices.

In conclusion, cutting diamonds is a complex and exacting process that combines artistry, science, and craftsmanship to transform rough diamond crystals into exquisite gemstones of unparalleled beauty and brilliance. From the initial selection of the rough stone to the final polishing of the finished diamond, each step requires skill, precision, and attention to detail to unlock the full potential of these precious earthly treasures.